In May 2012, when a devastating earthquake struck northern Italy, ARROW International CR, a manufacturer of medical supplies, faced a serious supply chain crisis. Overnight, the company lost its primary Italian supplier of components for the Hradec Králové plant and needed to find an immediate alternative. How did Martin Eger, the then Value Stream Manager, now Interim Manager of BM4U, deal with it? We’ll reveal all in an exclusive interview!

Martin, what were your first steps after learning that the earthquake in Italy had affected your main supplier?

We took an inventory of our stock practically overnight. The purchasing department found out how many parts we had on the way and at suppliers premises. We then prepared a simulation of how many of our products we could produce and for how long according to our long-term plans. I also addressed the situation with sales and marketing. We had to communicate with customers, explain to them what had happened and what steps we were taking to avoid panic. At the same time I requested support from the European R&D (research and development) department (at the expense of running projects) to prepare the ‘fastest’ variant of tests when changing the parts supplier.

How long did you look for alternative suppliers?

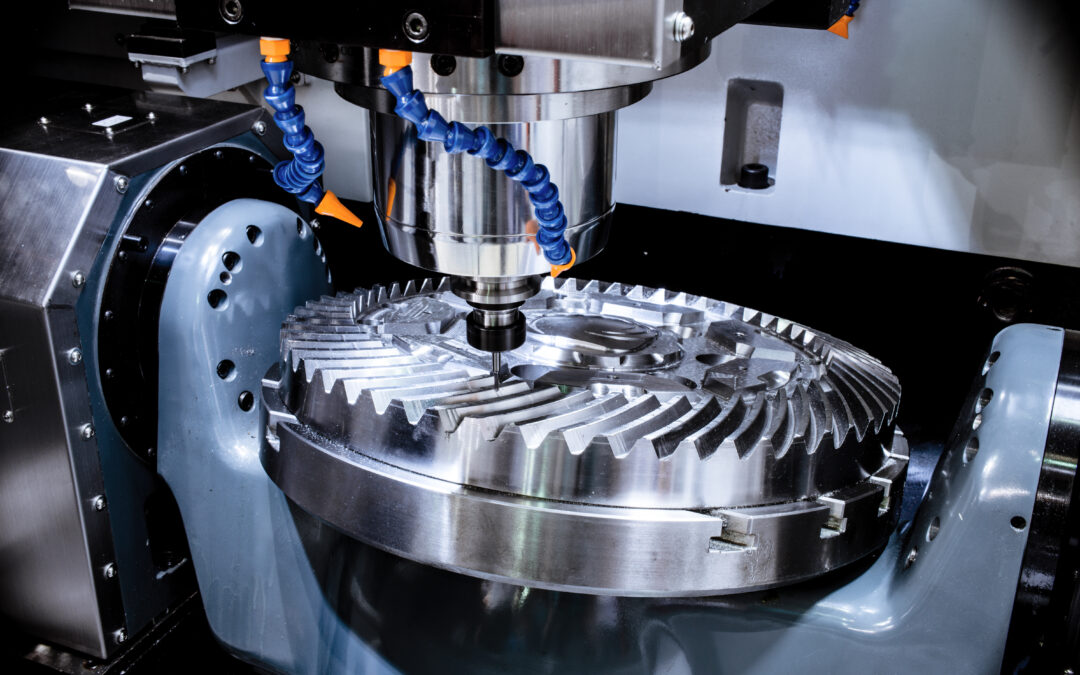

We didn’t really look for alternative suppliers, the products we lost were manufactured for us by our partners on our machines. To avoid extensive testing, we therefore thought of it as a production transfer from the beginning (existing machines, same material, just a different location).

How did the situation affect your clients?

We had to review existing orders and prioritise them according to importance and situation. Although we faced significant difficulties initially, we managed to minimise the impact on our customers thanks to the team’s quick response and hard work.

What came next?

We tried to renew supplies from Italy. Unfortunately, we found out that the partners in Italy had not provided the right information. They wanted to keep their jobs (which I understood), but they promised unrealistic things. We ultimately went to Italy personally, rescued our machines from the wreckage of the building and started to plan a move to Hradec Králové. When we got back, the research and development department, my process engineering team and I prepared a ‘daily’ action plan: what we needed to do and when we needed to do it so that we could use our components as quickly as possible. We also engaged HSE specialists and set minimum requirements for the machines to get them up and running. To do this we set out an upgrade plan, or what needed to happen to get the machines to a state that would be sustainable in the long term.

In the medical industry, any change to a product must go through a series of tests and verifications to ensure that the product is safe and performs its stated function throughout its useful life. If this were not the case, patients could be harmed or even die.

When were you able to resume full production?

We resumed full production by the end of the year, and even eliminated the backlog.

What measures have you put in place to prevent a similar situation from happening again in the future?

We have put in place more robust processes for risk management and supplier diversification. We have also strengthened our internal testing and development capabilities to make our response to similar crises faster and more effective in the future.

What lessons did you learn from this experience?

The key thing I would highlight is to have a good team that is loyal to the company, understands its expertise and is willing to prioritise the company’s needs in a crisis and to work with commitment, look for novel solutions, take responsibility for the solution and, last but not least, accept the risks of failure.

It is also important to have a crisis plan in place and maintain good relationships with clients and supply chain partners.